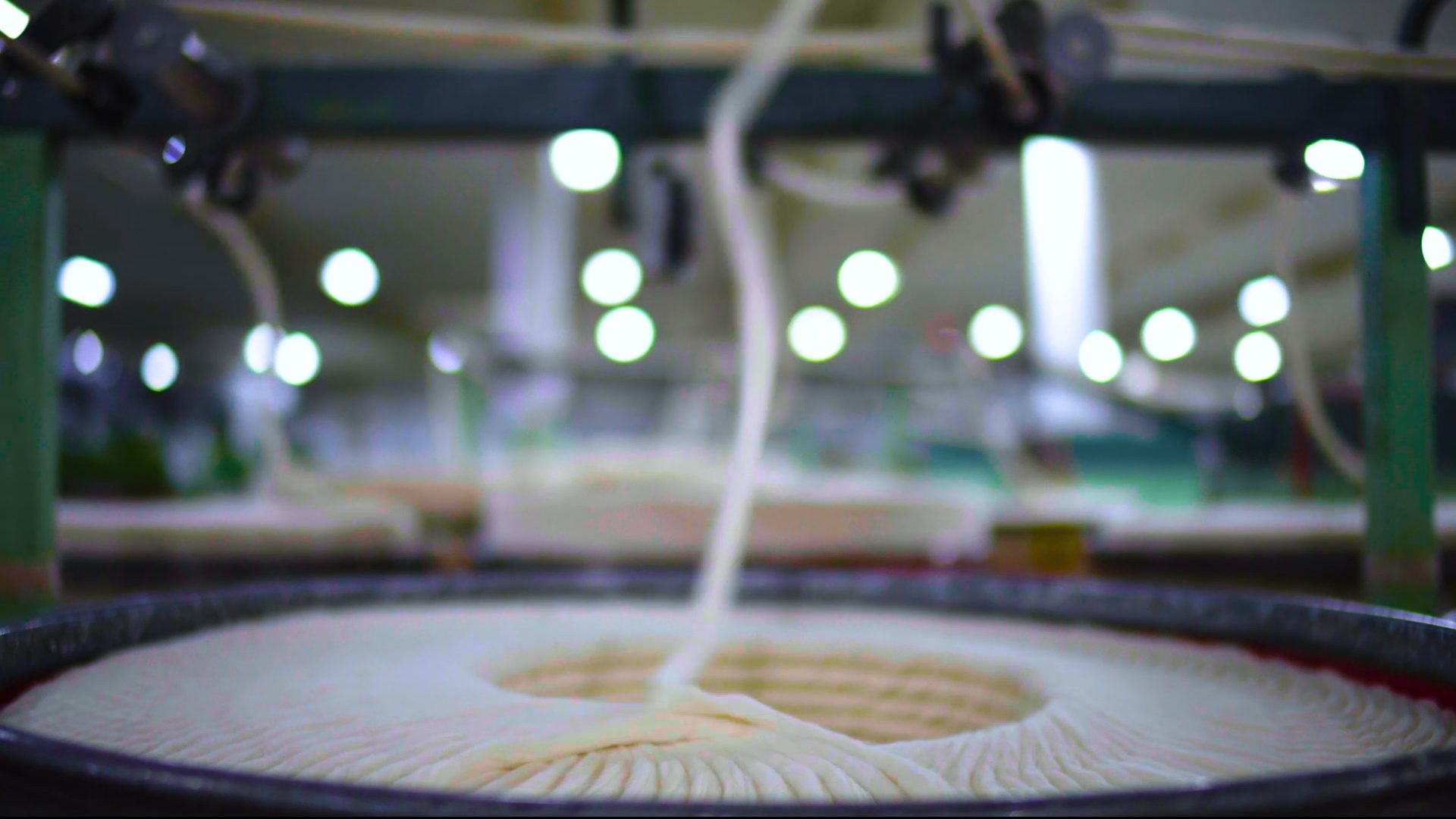

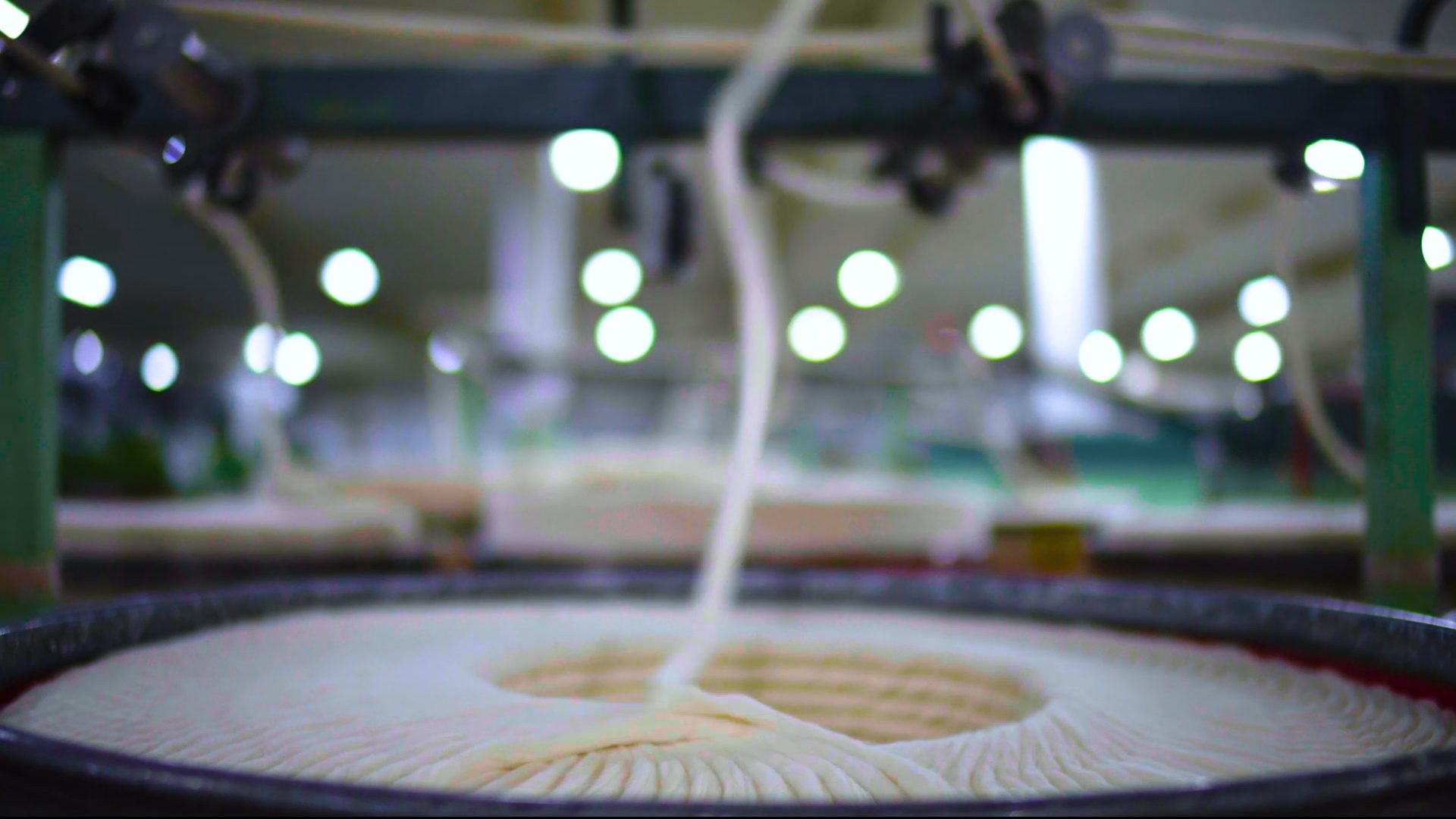

With the impressive production capacity of 80 million meters per year, our weaving department is all geared up to face the challenges of the textile industry. Our Weaving units are harnessed with 425 Sulzer Shuttle less looms, and 408 Air Jet looms along with recently installed 12 Air Jets for weaving. The weaving facilities are capable of producing twills, drills, dobbies, satins, sheeting, and other flawless finely woven fabrics. We use high grade quality of Pakistani Cotton, Pima, SMA and Egyptian Giza cotton, providing us a leading edge in high-end fabrics. We are in phase of addition of a 72 Air Jet Looms. Our custom built weaving facility is supported by the most modern yarn preparation equipment that is positioned in line with international standards. All the looms are equipped with latest data management systems and constantly control and monitor the efficiency of the looms which is comparable with the finest weaving plants in the world.

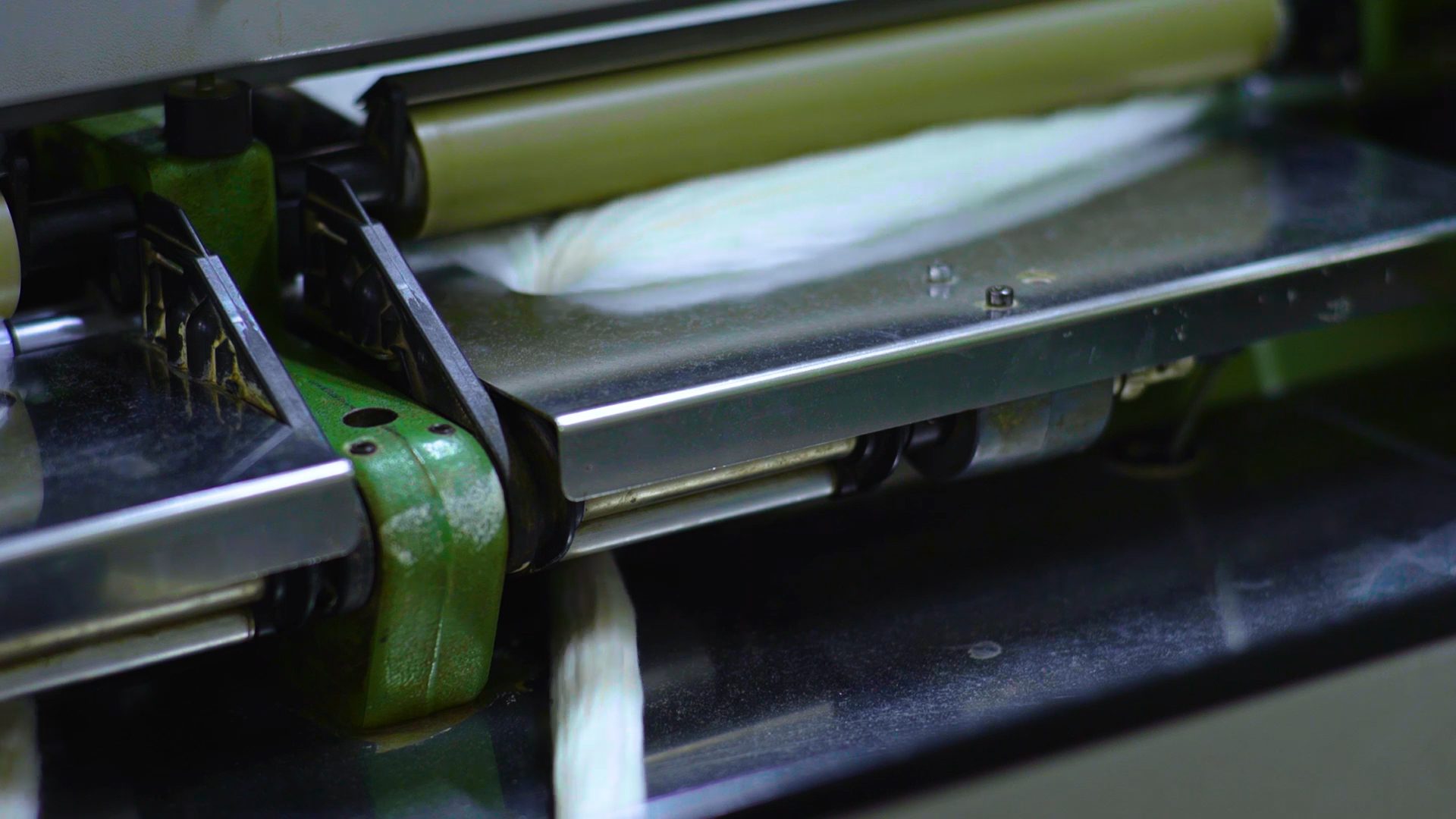

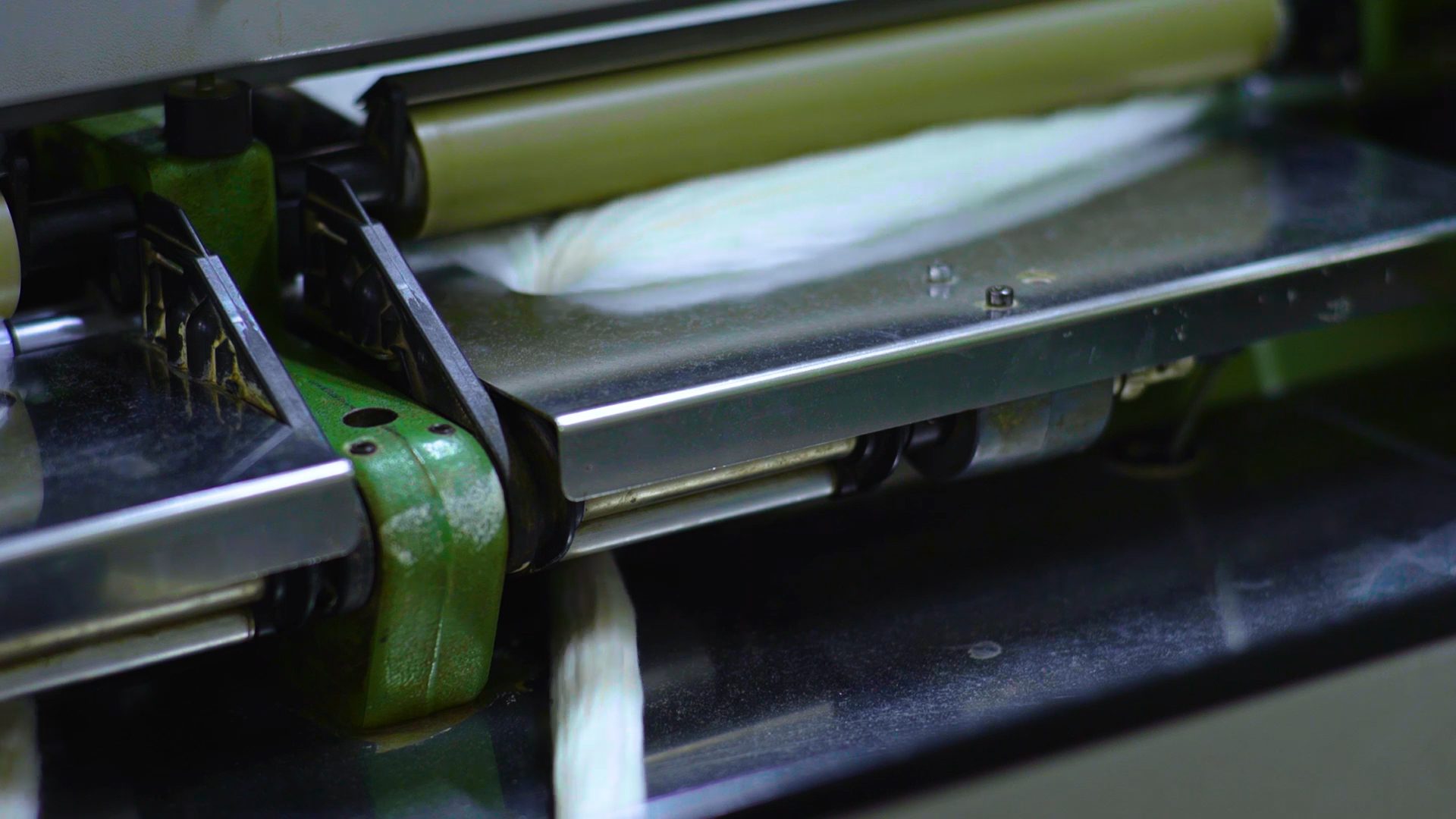

Our significant processing unit is highly proficient in printing, dyeing and finishing fabric up to 3.2 meters wide with an approximate production capacity of 8.5 million meters per month. The processing unit is based on the latest Swiss, German and Italian technology equipped with high tech machinery and equipment

The stitching division is equipped with sophisticated high tech machines that can stitch fabrics and transform them in to home textile as well as apparel products with a high degree of precision, correct to the micron. Our stitching machines including Juki, Brother, Kansai, and automated Texpa plant have combined capacity of 4.5million pcs per month totaling to 90 million units per annum for Home Textile and 17.5 million units per annum for Apparels and we encompass skilled labor force that is experienced in shaping the fabrics in to different sizes and styles as per client’s requirement. Customer orders are thoroughly scrutinized to ensure compliance with customer satisfaction before they reach their destination.

We are also teamed up with designers from USA, UK, France, which gives us an edge our competitors.

We have a vast range of designs catering to diversified global market. A computerized color kitchen enables production of exact shades time after time, effectively ensuring both consistency as well as reliability. Laser engraving

Being one of the finest printing facilities in the manufacturing world, we have the capability of printing up to 3.2 meters wide fabrics with a maximum color range up to 16 colors.

We are equipped with the latest Flatbed printing, with a printable width of 2.92 meters and table length of 52 meters. The flat bed printing machine can print up to 14 colors, depending upon the repeat size.

Apprehending the customer mindset prevailing in the market, and to fulfill the emerging requirements, Lucky Textile Mills has invested in heat transfer printing. The machine has the technology of sublimation printing – paper to fabric as well as direct printing on the fabric. The state of the art technology is equipped with high-efficiency drying system. Unlimited colors and repeat size.

At Lucky Textile Mills Limited, we endeavor to produce range of new colors. From the milky translucence of a misty morning to the pale hues of a clear blue sky, we are equipped with a continuous open width dyeing, thermosol and pad steam ranges that are capable of pigment, reactive and wet dyeing on international standards.

For shade verification, we use a spectrophotometer. Our color batch preparation is supported by both DATA color as well as Greg Macbeth color systems.

Without a proper check and balance, it’s nearly impossible to deliver excellence. Since we are strong believers in delivering reliable and quality products, we have one of the best textile laboratories equipped with the latest technology and are staffed with highly skilled and proficient people. We have an astounding capacity of covering a wide range of operations, starting from testing of the raw material till the evaluation of the final flawless product. Our quality procedures are on the guidelines of ISO 9001-2015 series of standards and our laboratories are well prepared to control and check at every stage of the production.

Lucky Textile Mills Limited is equipped to serve customer needs for specialized